RIGID-FLEX

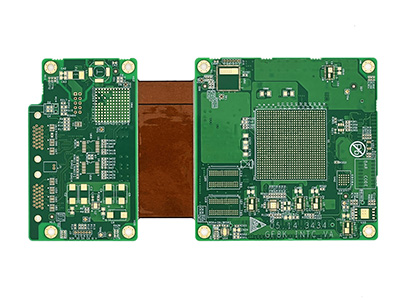

Traditional rigid flex construction (IPC-6013 type 4) Multilayer rigid and flexible circuit combination containing three or more layers with plated through holes.

Asymmetrical rigid flex construction, where the FPC is situated on the outer layer of the rigid construction. Containing three or more layers with plated through holes.

Multilayer rigid flex construction with buried / blind via (microvia) as part of the rigid construction. 2 layers of microvia are achievable. Construction may also include two rigid structures as part of a homogeneous build. Capability is 2+n+2 HDI structure.

Please contact us if you need further information or assistance, we are happy to help you.

FPC/ Rigid-flex PCB Manufacturing Capability | ||

Feature | Standard | Advanced |

Layer count | 6L | HDI 2 step |

Material Type | General flex, LCP, Panasoinc, Dupont, Shengyi, Taiflex | |

Board thickness | 0.04-2.0mm | |

Board thickness tolerance | ±0.05mm | |

Max size | 480*1200mm | |

Outline tolerance | ±0.05mm | |

Dielectric layer thinckness | 0.013-0.15mm | |

Outlayer copper thickness | 18-280um | |

Innerlayer copper thickness | 18-105um | |

Min line width/ space | 0.05mm | |

Finished hole size | 0.1-6.35mm | 0.05-6.35mm |

Hole tolerance | ±0.05mm | |

Hole position tolerance | ±0.05mm | |

Plugged hole size | 0.25-0.60mm | |

Thickness aperture ratio | 8:01 | |

Min. solder mask dam | 0.075mm | |

Min. solder mask isolation ring | 0.05mm | |

Coverlay | yellow, black, white, red | Others |

PI thickness | 12.5-25um | |

AD thickness | 15-50um | |

Stiffener | PI: 0.05-0.25MM, FR4, Al, copper | |

Impedance Tolerance | ±10% | |

Surface treatment | ENIG, immersion silver, OSP, gold finger | HAL, LF HAL |